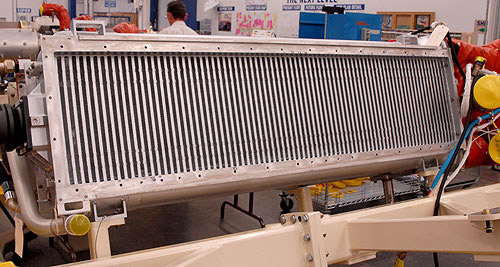

Aerospace Alloys, Inc. demonstrates our wide range of expertise across machining processes and materials, and in holding tight tolerances. Working with both aluminum material and nickel-based alloys, we carry out the entire manufacturing process of this heat exchanger’s parts. We put our EDM services to use in cutting aluminum bar and finned coil, and our abrasive waterjet cutting capability is used to cut the top frame shown in this image. A milling process is also applied to machine the frame to its finished size.

Since the units can be as large as several feet tall, to as small as a few inches, tight tolerance is of great importance. Every item manufactured for this unit is manufactured to within ± .001″ tolerance, ensuring proper operation and safety. Once all components are manufactured, we deliver them to our client for assembly within the unit. We are pleased to offer this service worldwide, with both national and international shipping options.